Q1.Siyini isizathu sokungathathi hlangothi kwe-silicone sealant ekhanyayo ibe phuzi?

Impendulo:

Ukuphuzi kwe-silicone sealant esobala engathathi hlangothi kubangelwa ukukhubazeka ku-sealant ngokwayo, ikakhulukazi ngenxa ye-ejenti exhumanisayo kanye nokuqina ku-sealant engathathi hlangothi. Isizathu siwukuthi lezi zinto ezimbili zokusetshenziswa ziqukethe “amaqembu e-amino”, asengozini enkulu yokuba phuzi. Ama-silicone sealant amaningi angenisiwe angenisiwe nawo analo mkhuba ophuzi.

Ukwengeza, uma i-neutral transparent sealant ye-silicone isetshenziswa ngesikhathi esifanayo ne-acetic silicone sealant, ingabangela i-neutral sealant ibe phuzi ngemva kokwelapha. Kungase futhi kubangelwe isikhathi eside sokugcinwa kwe-sealant noma ukusabela phakathi kwe-sealant ne-substrate.

I-OLV128 Transparent Neutral Silicone Sealant

Q2.Kungani umbala omhlophe we-silicone sealant kwesinye isikhathi uphenduka pink? I-sealant ethile iphenduka ibe mhlophe ngesonto ngemuva kokwelashwa?

Impendulo:

I-alkoxy ephulukisiwe yohlobo lwe-silicone sealant engathathi hlangothi ingase ibe nalesi simo ngenxa yokukhiqiza okuluhlaza kwe-titanium chromium compound. Inhlanganisela ye-Titanium chromium ngokwayo ibomvu, futhi umbala omhlophe we-sealant utholwa yi-titanium dioxide powder ku-sealant esebenza njengombala.

Kodwa-ke, i-sealant iyinto ephilayo, futhi ukusabela kwamakhemikhali amaningi emvelo kuyabuyiselwa emuva, kube nokusabela okuseceleni okwenzekayo. Izinga lokushisa liwukhiye wokubangela lokhu kusabela. Uma izinga lokushisa liphezulu, ukusabela okuhle nokubi kwenzeka, okubangela ukushintsha kombala. Kodwa ngemva kokuba izinga lokushisa lehla futhi lizinzile, ukusabela kuyahlehla futhi umbala ubuyela esimweni sawo sokuqala. Ngobuchwepheshe obuhle bokukhiqiza nobungcweti befomula, lesi simo kufanele sigwenywe.

Q3.Kungani omunye umkhiqizo we-sealant okhanyayo wasekhaya uphenduka umbala omhlophe ngemuva kwezinsuku ezinhlanu zokufaka isicelo? Kungani i-sealant eluhlaza engathathi hlangothi iphenduka umbala omhlophe ngemuva kokufakwa?

Impendulo:

Lokhu kufanele futhi kubangelwe yinkinga yokukhethwa kwezinto ezingavuthiwe nokuqinisekisa. Omunye umkhiqizo we-sealant osobala wasekhaya uqukethe ama-plasticizers aguquguquka kalula, kanti amanye aqukethe izigcwalisi eziqinisa kakhulu. Lapho ama-plasticizers eguquguquka, i-sealant iyancipha futhi ilula, iveze umbala we-fillers (zonke izigcwalisi ze-neutral sealant zimhlophe ngombala).

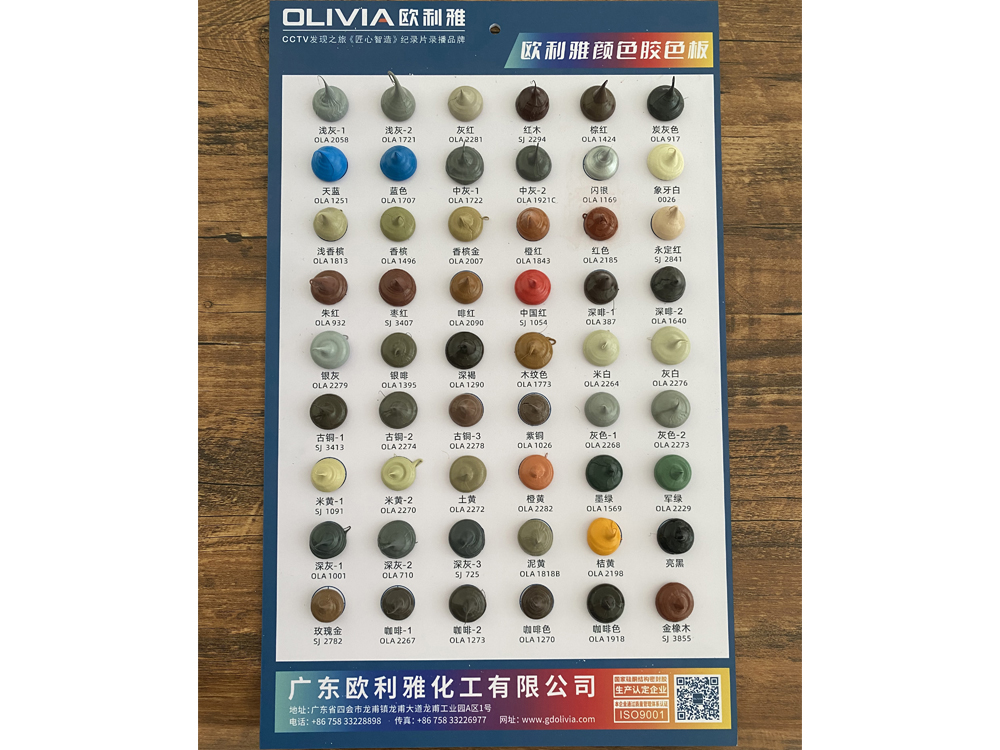

Ama-sealant anombala enziwa ngokungeza izingulube ukuze zibenze imibala ehlukene. Uma kunezinkinga ngokukhethwa kwe-pigment, umbala we-sealant ungashintsha ngemva kokufaka isicelo. Ngaphandle kwalokho, uma ama-sealant anemibala esetshenziswa azacile kakhulu ngesikhathi sokwakhiwa, ukushwabana okungokwemvelo kwe-sealant ngesikhathi sokwelashwa kungabangela umbala ukuthi ukhanye. Kulokhu, kunconywa ukugcina ubukhulu obuthile (ngaphezulu kuka-3mm) uma usebenzisa i-sealant.

Q4.Kungani kuvela amabala noma iminonjana esibukweni ngemva kokusebenzisa i-silicone sealant ngemuva kwe-isikhathi?

Impendulo:

Ngokuvamile kunezinhlobo ezintathu zokumboza ngemuva kwezibuko emakethe: i-mercury, isiliva elihlanzekile, nethusi.

Ngokuvamile, ngemva kokusebenzisa i-silicone sealant ukufaka izibuko isikhathi esithile, indawo yesibuko ingase ibe namabala. Lokhu kuvame ukubangelwa ukusebenzisa i-acetic silicone sealant, esabela ngezinto ezishiwo ngenhla futhi ibangele amabala endaweni yesibuko. Ngakho-ke, sigcizelela ukusetshenziswa kwe-sealant engathathi hlangothi, ehlukaniswe yaba izinhlobo ezimbili: i-alkoxy ne-oxime.

Uma isibuko esine-copper-backed sifakwe ne-oxime neutral sealant, i-oxime izogqwala kancane impahla yethusi. Ngemuva kwesikhathi sokwakha, kuzoba nezimpawu zokugqwala ngemuva kwesibuko lapho kufakwa khona i-sealant. Kodwa-ke, uma i-alkoxy neutral sealant isetshenziswa, lesi simo ngeke senzeke.

Konke lokhu okungenhla kungenxa yokukhethwa kwempahla engafanele okubangelwa ukuhlukahluka kwama-substrates. Ngakho-ke, kuyanconywa ukuthi abasebenzisi benze uhlolo lokusebenzisana ngaphambi kokusebenzisa i-sealant ukuze babone ukuthi i-sealant iyahambisana yini nokokusebenza.

Q5.Kungani amanye ama-silicone sealant ebonakala njengama-granules usayizi wamakristalu kasawoti lapho esetshenziswa, futhi kungani amanye alawa ma-granules azincibilika ngokwawo ngemva kokwelapha?

Impendulo:

Lokhu kuyinkinga ngefomula yempahla eluhlaza esetshenziswa ekukhetheni i-silicone sealant. Amanye ama-silicone sealant aqukethe izinto ezixhumanisayo ezingacwebezela emazingeni okushisa aphansi, okubangela ukuthi i-ejenti yokuxhumanisa iqine ngaphakathi kwebhodlela elinamathelayo. Ngenxa yalokho, lapho okunamathelayo kukhishwa, ama-granules afana nosawoti anobukhulu obuhlukahlukene angase abonakale, kodwa azoncibilika kancane kancane ngokuhamba kwesikhathi, okwenza ama-granules anyamalale ngokuzenzakalelayo ngesikhathi sokwelashwa. Lesi simo sinomthelela omncane kwikhwalithi ye-silicone sealant. Isizathu esiyinhloko salesi simo umthelela omkhulu wamazinga okushisa aphansi.

Q6.Yiziphi izizathu okungenzeka ukuthi kungani enye i-silicone sealant ekhiqizwa ekhaya efakwe engilazini ihluleke ukwelapha ngemva kwezinsuku eziyi-7?

Impendulo:

Lesi simo sivame ukwenzeka lapho kubanda.

1.I-sealant isetshenziswa ibeminyene kakhulu, okuholela ekwelapheni kancane.

2.Indawo yokwakha ithintwa isimo sezulu esibi.

3.I-sealant iphelelwe yisikhathi noma ayinasici.

4.I-sealant ithambile kakhulu futhi izizwa ingakwazi ukwelapha.

Q7.Siyini isizathu samabhamuza avelayo lapho kusetshenziswa imikhiqizo ethile ye-silicone sealant ekhiqizwa ekhaya?

Impendulo:

Kungase kube nezizathu ezintathu ezingenzeka:

1.Ubuchwepheshe obumpofu ngesikhathi sokupakisha, okwenza umoya uvaleleke ebhodleleni.

I-2.Abakhiqizi abambalwa abangenangqondo ngamabomu abaqinisi i-cap engezansi ye-tube, beshiya umoya ku-tube kodwa banikeze umbono wevolumu eyanele ye-silicone sealant.

3.Amanye ama-silicone sealant akhiqizwa ekhaya aqukethe izihlungi ezingasabela ngamakhemikhali ngepulasitiki ethambile ye-PE yeshubhu yokupakisha ye-silicone sealant, okubangela ukuthi ishubhu lepulasitiki livuvuke futhi lenyuke ukuphakama. Ngenxa yalokho, umoya ungangena esikhaleni ngaphakathi kweshubhu futhi ubangele ama-voids ku-silicone sealant, okuholela kumsindo wamabhamuza ngesikhathi sokufaka isicelo. Indlela ephumelelayo yokunqoba lesi simo ukusebenzisa ukupakishwa kweshubhu nokunaka indawo yokugcina umkhiqizo (ngaphansi kuka-30 ° C endaweni epholile).

Q8.Kungani amanye ama-silicone sealant angathathi hlangothi asetshenziswa lapho kuhlangana khona ukhonkolo kanye namafreyimu ewindi ensimbi akha amabhamuza amaningi ngemva kokwelapha ehlobo, kuyilapho amanye engenzi? Ingabe inkinga yekhwalithi? Kungani izenzakalo ezifanayo zingenzeki ngaphambili?

Impendulo:

Izinhlobo eziningi ze-silicone sealant ezingathathi hlangothi ziye zabhekana nezimo ezifanayo, kodwa empeleni akuyona inkinga yekhwalithi. Ama-sealants angathathi hlangothi afika ngezinhlobo ezimbili: i-alkoxy ne-oxime. Futhi ama-alkoxy sealants akhulula igesi (i-methanol) ngesikhathi sokwelashwa (i-methanol iqala ukuhwamuka cishe ku-50℃), ikakhulukazi uma ichayeke elangeni eliqondile noma amazinga okushisa aphezulu.

Ngaphezu kwalokho, amafreyimu amafasitela kakhonkolo kanye nensimbi awakwazi ukungena emoyeni, futhi ehlobo, ngokushisa okuphezulu nomswakama, i-sealant iphulukisa ngokushesha. Igesi ekhishwe ku-sealant ingaphuma kuphela ongqimbeni olulapheke kancane lwe-sealant, okwenza amabhamuza anosayizi abahlukene avele ku-sealant eselashiwe. Nokho, i-oxime neutral sealant ayikhiphi igesi phakathi nenqubo yokwelapha, ngakho ayikhiqizi amabhamuza.

Kodwa okubi kwe-oxime neutral silicone sealant ukuthi uma ubuchwepheshe nokubunjwa kungaphathwa kahle, kungase kushwabane futhi kuqhekeke ngesikhathi senqubo yokwelapha esimweni sezulu esibandayo.

Esikhathini esidlule, izenzakalo ezifanayo azizange zenzeke ngenxa yokuthi ama-silicone sealant ayengavamile ukusetshenziswa ezindaweni ezinjalo ngamayunithi okwakha, futhi izinto zokuvala ama-acrylic ezingangeni manzi zazivame ukusetshenziswa esikhundleni salokho. Ngakho-ke, ukwenzeka kwe-bubbling ku-silicone neutral sealant yayingavamile kakhulu. Eminyakeni yamuva, ukusetshenziswa kwama-silicone sealants kuye kwanda kancane kancane, kuthuthukisa kakhulu izinga lekhwalithi yobunjiniyela, kodwa ngenxa yokuntuleka kokuqonda izici ezibonakalayo, ukukhethwa kwezinto ezingalungile kuye kwaholela emvelweni we-sealant bubbling.

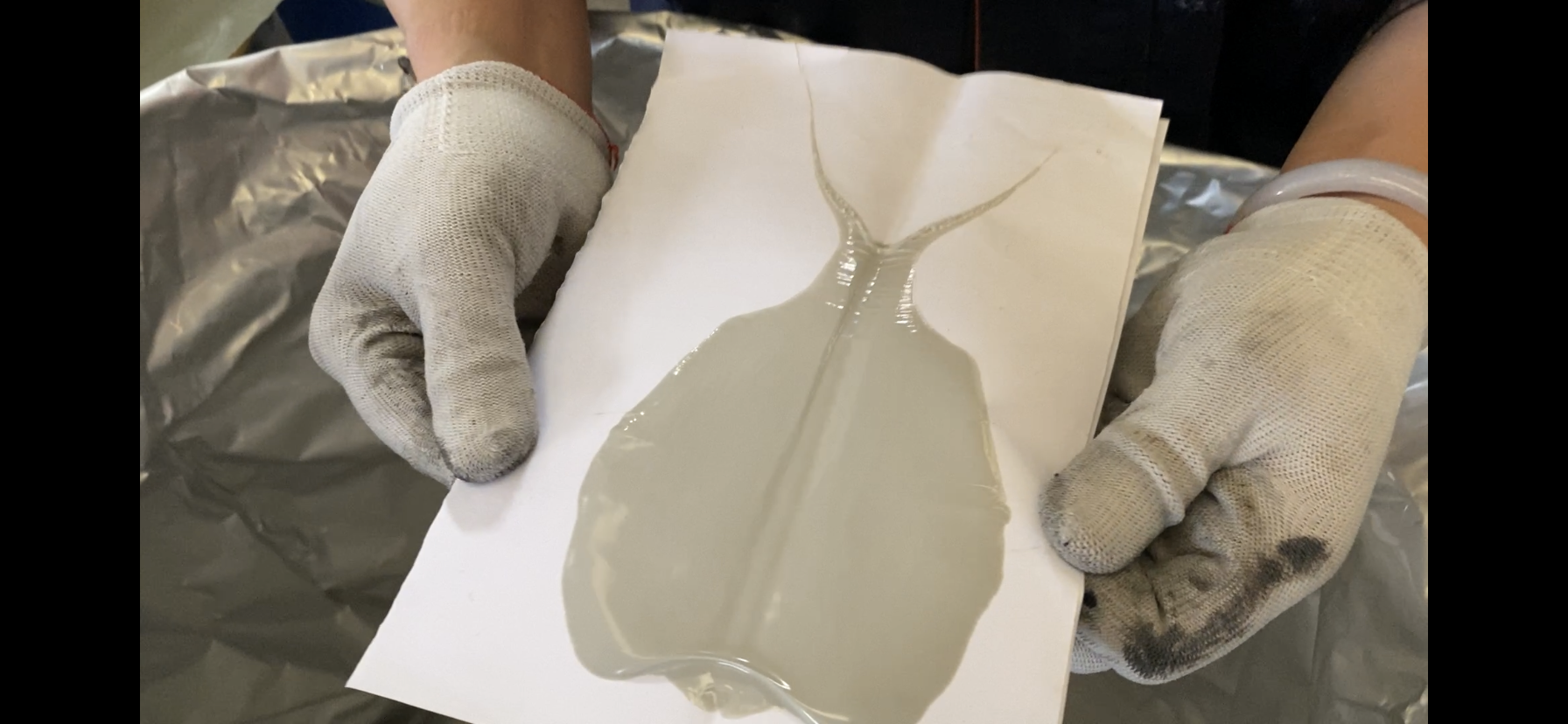

Q9.Indlela yokwenza ukuhlolwa kokuhambisana?

Impendulo:

Uma sikhuluma ngokuqinile, ukuhlolwa kokuhambisana phakathi kokunamathelayo nama-substrates wokwakha kufanele kwenziwe yiminyango kazwelonke yokuhlola impahla yokwakha eyaziwayo. Nokho, kungase kuthathe isikhathi eside futhi kubize kakhulu ukuthola imiphumela ngale minyango.

Kumaphrojekthi adinga ukuhlolwa okunjalo, kuyadingeka ukuthola umbiko wokuhlola ofanelekayo ovela esikhungweni sokuhlola esigunyaziwe sikazwelonke ngaphambi kokunquma ukuthi uzosebenzisa umkhiqizo othile wempahla yokwakha. Kumaphrojekthi ajwayelekile, i-substrate inganikezwa umenzi we-silicone sealant ukuze ahlolwe ukuhambisana. Imiphumela yokuhlola ingatholwa cishe ezinsukwini ezingama-45 ye-structural silicone sealant, kanye nezinsuku ezingama-35 ze-neutral and acetic silicone sealant.

Q10.Kungani i-acetic silicone sealant ixebuka kalula kusimende?

Impendulo: Ama-acetic silicone sealants akhiqiza i-asidi ngesikhathi sokuphulukiswa, esabela ngobuso bezinto ze-alkaline ezifana nosimende, imabula, ne-granite, okwenza into e-chalky enciphisa ukunamathela phakathi kwe-adhesive ne-substrate, okwenza i-asidi sealant ikhiphe kalula kusimende. Ukuze ugweme lesi simo, kuyadingeka ukusebenzisa i-adhesive engathathi hlangothi noma i-oxime efanelekile kuma-alkaline substrates ukuze uvalwe futhi ubophe.

Isikhathi sokuthumela: May-16-2023